- Helicon

- 9

- Kissimmee Sinkhole Foundation Repair: Injection Push Piers and Pressure Grout Stabilize a Home

Kissimmee Sinkhole Foundation Repair: Injection Push Piers and Pressure Grout Stabilize a Home

Kissimmee, FL

Market: Residential

Solution: Foundation Repair

Services: Underpinning & Pressure Grouting

The Project

Property: Single‑family residence on shallow foundations in Kissimmee, FL.

Problem: A long‑standing, unrepaired sinkhole had undermined near‑surface soils and created a risk of differential settlement.

Stakeholders: Homeowner; AWARD Engineering (Engineer of Record); Helicon field and project management teams.

Objectives: 1. Isolate the structure from weak/voided near‑surface soils by transferring loads to competent strata.

2. Densify and reconsolidate the soil mass within and above the karst‑influenced zone.

3. Deliver a documented, code‑aligned repair with minimal disruption to the homeowner.

Why action was urgent: Karst processes—dissolution of limestone, migration of fines, episodic void formation—make sinkhole sites unpredictable. Surface symptoms (cracking, racked doors, slab separations) may lag behind the subsurface reality. The best protection is an engineered deep‑support system coupled with targeted ground improvement.

The Challenge

Remediating a sinkhole is not the same as patching a crack. Three realities framed the design and means and methods:

- Unknown subsurface geometry: Karst voids are irregular. A plan must be robust to variable depths and non‑uniform strength.

- Do no harm: Aggressive excavation or uncontrolled grouting can create new pathways or shift loads abruptly. All actions must be metered, monitored, and reversible until performance is confirmed.

- Occupied‑home constraints: Access, noise, and housekeeping matter. The homeowner needed a program that preserved daily life while addressing a high‑risk condition beneath the structure.

Site & Geotechnical Context (Karst in Central Florida)

Osceola County lies within Florida’s karst belt, where limestone at depth is subject to chemical dissolution. Over time, this produces voids and conduits. When overlying sands and clays slough into those spaces, near‑surface settlement follows. Effective remediations typically combine:

- Deep underpinning (to bypass weak soils and seat loads on competent horizons), and

- Pressure grouting (to densify loose zones, fill voids, and interrupt migration pathways).

This project applied both, phased to avoid over‑pressurization and to confirm structural response before soil mass improvement.

The Solution

Helicon installed thirty‑two (32) hydraulically driven steel push piers along select exterior wall lines. Each pier location was chosen to intercept load paths from the superstructure and to create a continuous, redundant support ring around the affected areas. After all piers were driven to refusal at 28–114 feet, the team executed a pressure‑grouting program that injected ~30 cubic yards of grout through and around the pier network. The grouting phase served to fill remaining voids, stiffen the matrix, and couple the piered footing system to a densified soil mass for uniform performance.

Why Push Piers for Sinkhole Repair

- Direct load transfer: Push piers are advanced until installation resistance indicates competent bearing; the building’s weight is then transferred to this deeper stratum, bypassing problem soils.

- Verifiable capacity: Drive pressures and refusal behavior provide a measurable proxy for axial capacity during installation.

- Low disturbance: Small exterior excavations and compact hydraulic equipment minimize disruption and facilitate neat restoration.

Why Follow with Grout Injection

- Void closure: Grout fills karst cavities and chimneys that could otherwise continue to migrate fines.

- Load sharing: A densified soil matrix shares load between piers and improved ground, reducing stress concentrations at brackets.

- Pathway disruption: Pressure grout interrupts preferential flow paths, decreasing the chance of future raveling.

Field Execution & QA/QC

- Layout & Utility Locates

Crews marked utilities, planned access, and established clean work zones. Pier locations mirrored structural demand (corners, high‑load walls, and areas near observed distress). - Footing Access

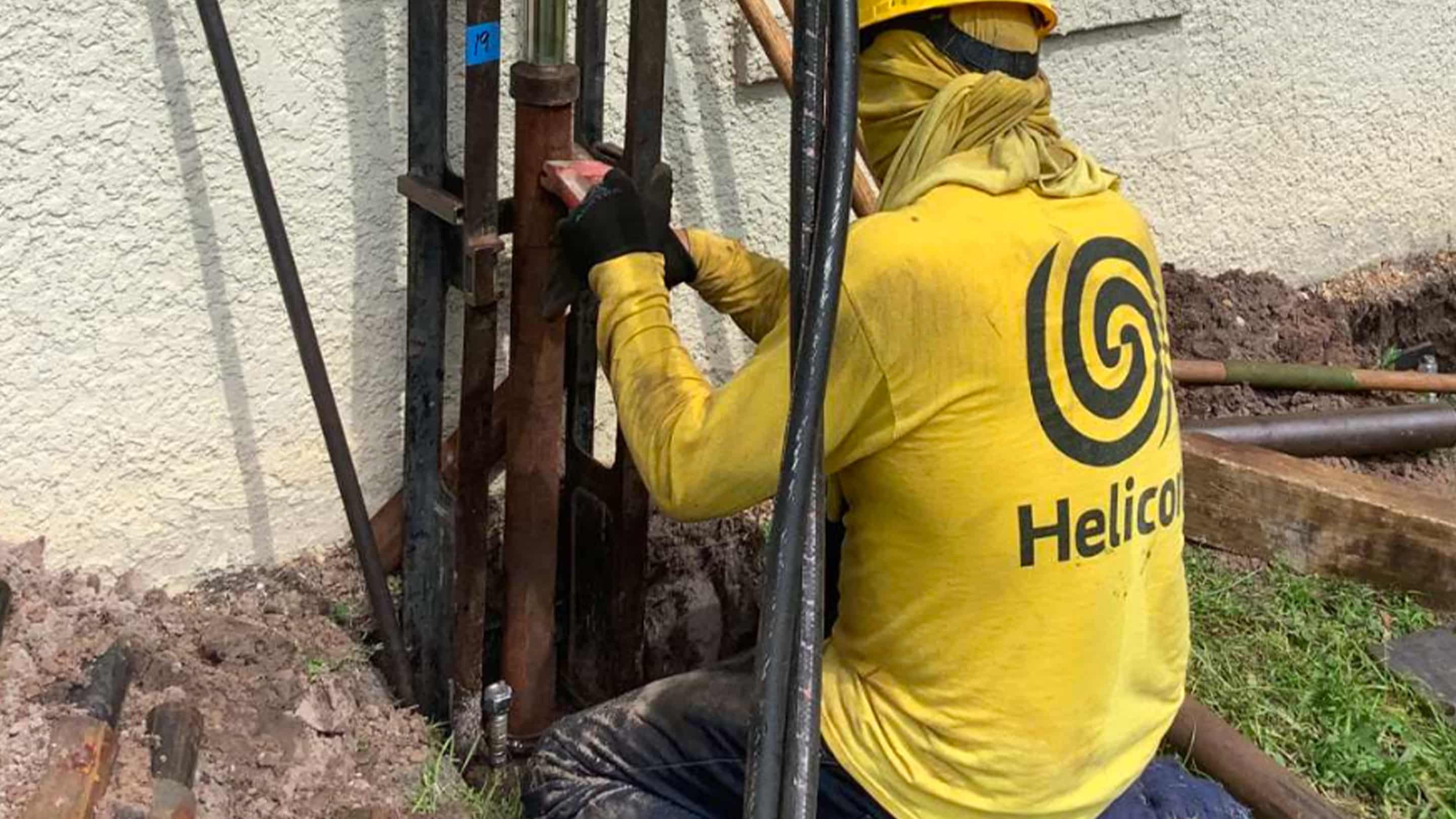

Small pits exposed the footing at each location. Brackets were set per manufacturer/engineer specifications after footing prep. - Pier Driving to Refusal

Steel pier segments were driven with hydraulics in 5‑foot increments to 28–114 feet, depending on local conditions. Refusal confirmed bearing. Drive forces were logged. - Load Transfer & Stabilization

Upon reaching target resistance, a portion of the structure’s weight was transferred to the pier system. Any lift attempts were performed conservatively and only where structural response allowed. - Pressure Grouting

With deep support in place, crews injected ~30 yd³ of grout using controlled pressures and staged lifts, working outward from the footing to fill voids and stiffen the treatment zone. - Documentation & Engineer Oversight

Production logs captured pier depths, drive resistance, and grout volumes. AWARD Engineering reviewed results and issued an opinion of stabilization at piered locations.

Results & Benefits

- Foundation Repair Stabilized at the Source

Loads now bear on competent strata via 32 push piers; the structure is decoupled from problematic soils that had been influenced by sinkhole activity. - Ground Improvement Achieved

The ~30 cubic yards of pressure grout closed voids and densified the soil mass within the influence zone—reducing the potential for future migration and settlement. - Documented Conformance

The Engineer of Record concluded that the repair was completed in accordance with accepted industry standards and that the foundation at treated locations is stabilized. - Minimal Disruption

Work was executed from the exterior with compact equipment and small excavations; the home remained habitable throughout; final cleanup restored landscaping and access points. - Peace of Mind

The homeowner now has an engineer‑backed solution with logs and as‑built data for future refinancing, resale, or insurance inquiries.

Homeowner FAQs (Sinkholes & Underpinning)

Can you lift the house back to perfectly level?

Our first mandate is stability. Where footings and framing safely allow, we may pursue measured lift during load transfer; however, complete restoration to original elevations is not always prudent. The goal is a stable, uniform platform that stops further damage.

How deep do push piers go?

Depth is governed by where we find competent bearing—in this case, 28–114 ft. Depth itself is less important than verified capacity at refusal and performance of the system under load.

Why add grout after underpinning?

Grouting fills voids, stiffens loose soils, and interrupts pathways that move fines toward the sinkhole. It complements the piers by improving the soil mass that supports slabs, grade beams, and utilities.

Will the sinkhole reopen somewhere else?

Karst terrain is dynamic. The combined strategy—deep support + ground improvement—reduces risk by decoupling the structure from shallow soils and inhibiting further raveling in the treated zone. Regular drainage maintenance and observation remain good practice.

How long will this last?

Steel push piers deliver a permanent load path when installed to competent strata and protected from corrosion per manufacturer/engineer guidance. Grouted soils retain improved stiffness; performance depends on site drainage and regional hydrogeology.

Maintenance & Monitoring

- Drainage Management: Keep roof runoff directed away from foundations; maintain gutters and downspouts.

- Irrigation Discipline: Avoid chronic saturation adjacent to footings; monitor for ponding.

- Landscape Planning: Limit large new trees near foundations; root decay can influence shallow soils over time.

- Seasonal Walk‑Arounds: Photograph repaired cracks/doors quarterly; call if notable changes appear.

- Records Retention: Keep pier logs and grout tickets with your property files for future reference.

About Helicon

Helicon is Florida’s trusted partner for foundation repair, sinkhole remediation, soil stabilization, and concrete lifting. We serve homeowners across Osceola County and Greater Orlando, delivering engineered, minimally disruptive solutions backed by clear documentation and a dedicated customer experience.

Seeing cracks, sticking doors, or depressions near your Kissimmee home? Don’t wait on karst. Helicon’s engineer‑guided teams design and install push pier + grout solutions that stabilize foundations without major demolition. Call 844‑HELICON to schedule a free inspection and get an expert plan for your property

FREE INSPECTION REQUEST